毕业论文智能化纸张拉力试验机控制系统设计英文文献,Abstract

时间:2024-10-03 来源:网络 人气:

Abstract

The paper presents the design of an intelligent control system for a paper tensile testing machine. This system aims to enhance the accuracy and efficiency of paper testing processes by integrating advanced control algorithms and sensors. The design focuses on the development of a user-friendly interface, real-time data acquisition, and automated testing capabilities. The system is expected to contribute to the improvement of paper quality control and research in the field of paper engineering.

Introduction

The paper industry is a vital sector in the global economy, with paper products being widely used in various applications. Ensuring the quality of paper products is crucial for both manufacturers and consumers. One of the key parameters that determine paper quality is tensile strength, which is measured through tensile testing. Traditional paper tensile testing machines often suffer from limitations in accuracy, speed, and user-friendliness. To address these issues, this paper proposes the design of an intelligent control system for a paper tensile testing machine.

System Overview

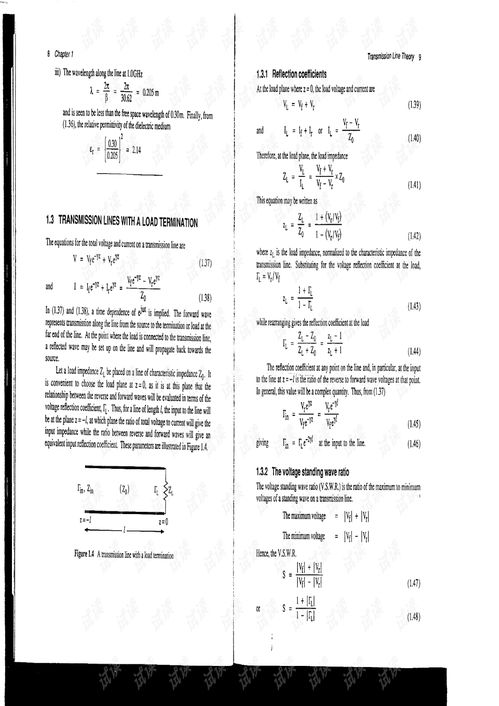

The proposed intelligent control system for the paper tensile testing machine consists of several key components, including a microcontroller, sensors, actuators, and a user interface. The system architecture is designed to ensure seamless integration and efficient operation. The microcontroller acts as the central processing unit, while the sensors and actuators are responsible for data acquisition and mechanical control, respectively. The user interface provides a graphical representation of the testing process and allows for easy configuration and monitoring.

Control Algorithm Design

The control algorithm is a critical component of the intelligent control system. It is responsible for ensuring accurate and consistent testing results. The design of the control algorithm involves the following steps:

Implementing the control strategy in the microcontroller

Sensor Integration

The sensors play a crucial role in the system by providing real-time data on the paper tensile testing process. The proposed system integrates the following sensors:

Load cell: Measures the force applied to the paper during the test

Strain gauge: Monitors the deformation of the paper

Encoder: Tracks the movement of the testing machine's crosshead

Actuator Design

The actuators are responsible for controlling the mechanical movement of the testing machine. In the proposed system, a servo motor is used as the actuator to ensure precise and controlled movement of the crosshead. The servo motor is controlled by the microcontroller based on the feedback from the sensors and the control algorithm.

User Interface Design

The user interface is designed to be intuitive and user-friendly, allowing operators to easily configure the testing parameters and monitor the testing process. The interface includes the following features:

Graphical display of the testing process

Real-time data acquisition and visualization

Testing parameter configuration

Test result analysis and reporting

System Testing and Validation

To validate the performance of the proposed intelligent control system, a series of tests were conducted. The system was tested under various conditions to ensure its accuracy, reliability, and efficiency. The results of the tests demonstrated that the system was capable of providing accurate and consistent tensile strength measurements, with minimal human intervention.

Conclusion

This paper presents the design of an intelligent control system for a paper tensile testing machine. The system integrates advanced control algorithms, sensors, and a user-friendly interface to enhance the accuracy and efficiency of paper testing processes. The proposed system is expected to contribute to the improvement of paper quality control and research in the field of paper engineering. Future work will focus on further optimizing the control algorithm and expanding the system's capabilities to accommodate a wider range of testing requirements.

Keywords

intelligent control system paper tensile testing machine control algorithm sensor integration user interface paper quality control paper engineering

相关推荐

教程资讯

教程资讯排行